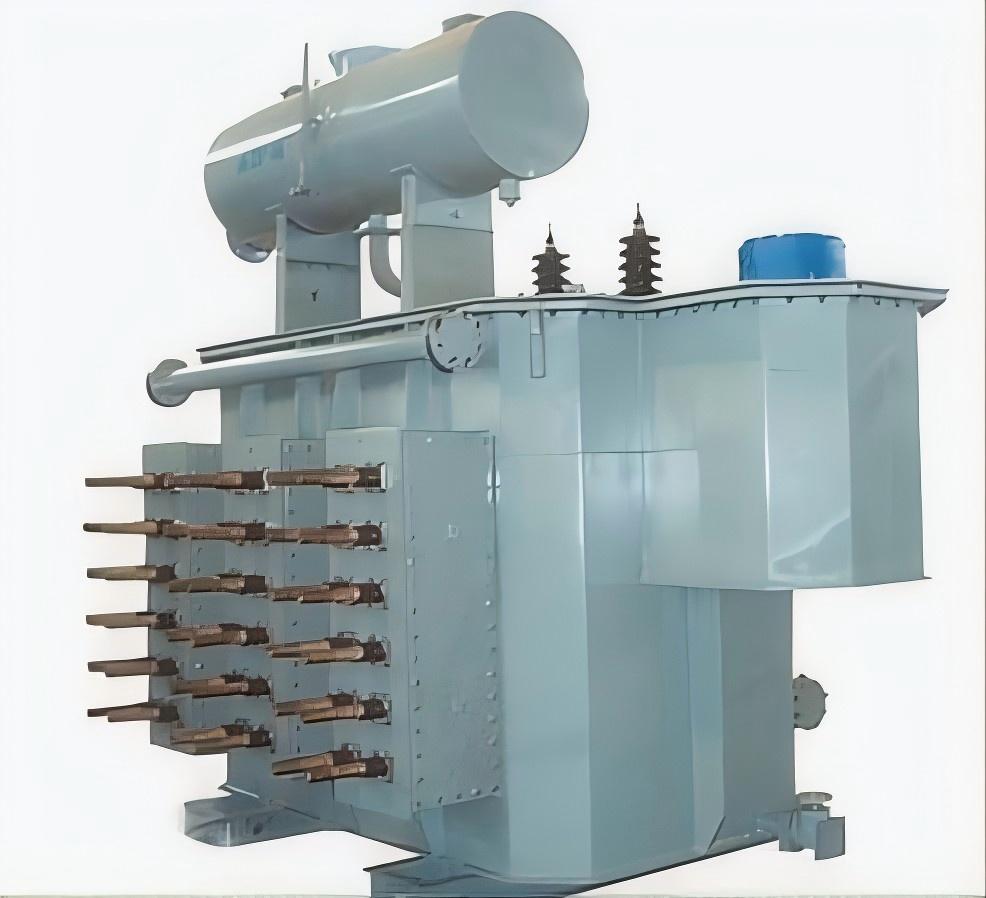

Our company is capable of designing and producing electric arc furnace transformers of all capacities,including calcium carbide furnace transformers, ferrosilicon furnace transformers, steel ladle refiningfurnace transformers, electrostatic furnace transformers, and yellow phosphorus furnace transformers,among others. Transformers of all models are specifically designed for the power supply requirementsfor the smelting of metals (steel and iron alloys) and non-metals (calcium carbide, etc.) electric furnac1.The structure of these transformers can generally be divided into two types: those without electricreactor and those with electric reactor, with both high and low impedance designs to meet the diverseneeds of users. The iron cores are made of high-quality grain-oriented silicon steel sheets, which areprocessed on a slicing production line of silicon steel sheets imported from Germany to stack the ironcores into multistage circular cross-sections, ensuring low noise and low losses. The coils are designedby our engineers using computers to accurately calculate magnetic, electrical, and mechanical parameters while taking into account the actual situation of users, significantly reducing the eddy currentlosses that are difficult to control in transformers of electric furnaces in the same industry, thus guaranteeing low power consumption, safety, and stability for users. The transformer enclosures are coatedwith electrostatic spray technology, and the steel plate surfaces are treated with advanced techniquesto enhance the adhesion of the paint, which is not merely aesthetically pleasing but characterized bygood toughness, corrosion resistance, wear resistance, and does not fade.

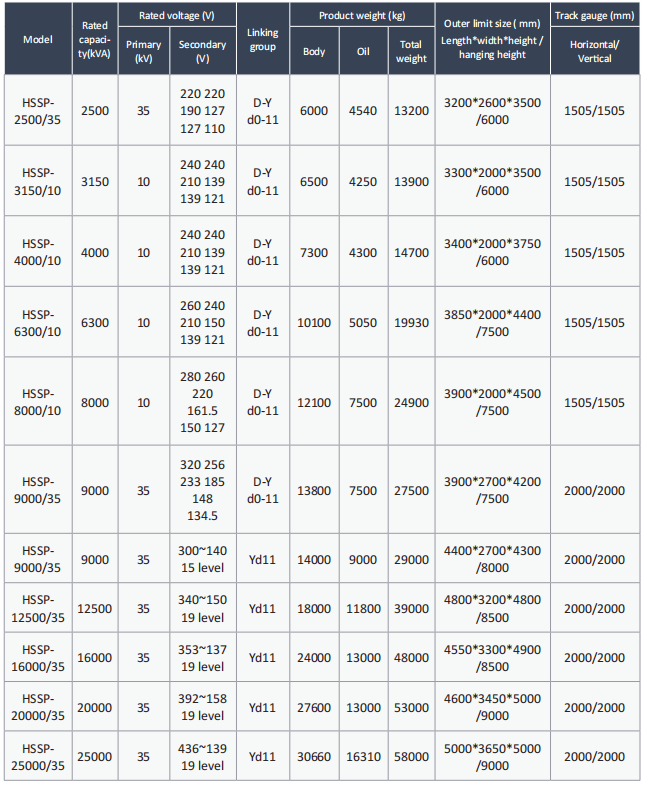

Technical parameters

HSSP series (HP) and (UHP) series electric arc furnace transformer technical parameter

Return

Return 吉公安备案号1600888999

吉公安备案号1600888999